Monitor & Control Underground Mine Pumps!

Submersible pumps are frequently used in underground mines, and while installing these pumps is not particularly challenging, managing mine sumps has frustrated operators for years. Although pump installation itself may be straightforward, the ongoing management of sump systems often proves to be a persistent issue. Pumps are essential to mine operations, yet they typically remain a low priority until pump costs start spiraling out of control, negatively impacting financial performance, or pump failures result in washed-out roads or flooded work areas.

Mine sumps, in particular, can become a significant inconvenience as they fill with silt from mining activities, requiring periodic cleaning. When sumps become clogged with silt, mine water bypasses the sump altogether. As a result, without fluid reaching the pump, it can run dry and sustain damage.

Another common scenario occurs when underground operators notice a mine sump filling with water, but the pump is not running. Believing they should take action, they switch the pump into manual mode, start it, and then leave to attend to other duties. However, in manual mode, the pump continues to run regardless of the sump’s water level. This often leads to the pump running dry and ultimately failing. Unfortunately, this is a daily occurrence in underground mining, though these failures are entirely avoidable.

What is the SC10 Pump Controller

The SC10 is a microprocessor-based pump controller specifically designed for controlling submersible pumps in mining operations. It features digital inputs, digital outputs, and a Modbus RS485 communications port. The controller uses the Modbus RTU protocol to facilitate communications with HMI, SCADA, or PLC systems.

This pump controller is engineered to optimise submersible pump operation and sump level control by incorporating snore detection technology. By monitoring the motor current, the unit can detect when the pump begins “snoring,” a condition that occurs when minimal fluid is being pumped, indicated by a reduction in electrical current. Once snoring is detected, the controller automatically places the pump in pause mode. (See below for more details on snoring.)

Snore controllers have been available for some years but they have not evolved. The SC10 has added the following:

- PCommunications for monitoring and control from SCADA.

- PIntelligent, adaptive pause control to optimise the pause times.

- PSupport for Starting without switching to Manual Operation to prevent damage.

- PSafety features so that you can make adjustments without working in a live starter.

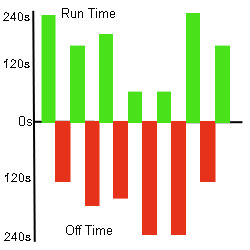

The SC10 manages the duration of pump run and pause time using an advanced adaptive control algorithm. It increases and decreases run and pause times based on operational history to produce the most efficient parameters. The pump can also be started at anytime during the automatic cycle using the pump starter panel start button and ensures the pump can never be left in manual to run dry.

Why Not Monitor Your Mine Pumps?

Today the majority of underground mines have leaky feeder radio or Wi-Fi communication systems installed making it very easy to get information from underground to the surface in real time. In the past to monitor your pumps it required the installation of additional equipment such as programmable logic controllers (PLC) in pump starters, this required additional technical expertise to install and program each pump starter. This works, but is expensive and you still require a solution for the effective operation of the pump and sump level control.

Today there is no reason not to monitor your underground infrastructure including pumps.

In the past to monitor your pumps it required the installation of additional equipment such as programmable logic controllers (PLC) in pump starters, this required additional technical expertise to install and program each pump starter. This works, but is expensive and you still require a solution for the effective operation of the pump and sump level control.

The SC10 is a practical solution for montoring mine pumps

A practical solution is to use a specifically-designed pump controller that has communication capabilities so you can connect to your communications network and display on your mine control system. The you can start, stop and monitor the status of all your submersible pumps from a central location. It couldn’t be easier than this! Install an off the shelf pump snore controller, connect it to your underground communications network with a Modbus to Wifi convertor or Modbus radio Modem and configure you mine control interface.

What is pump Snoring?

Pump snoring is a condition that occurs when a pump is running with a mixture of water and air during operation. This phenomona causes mechanical and thermal stress reducing component life.

When there is not adequate fluid flowing to transport sediments away they accumulate within the pump and cause premature wear to pump parts driving costs up.

Detecting this event is quite simple as the the motor load current (Amps) decreases and is used as a signal to stop the pump. While there are other options to control sump levels snore detection isthe best solution for mine and construction activities.

What is Modbus RTU Protocol?

Modbus is a very widely used industrial communications protocol. It is supported by all major SCADA packages, many communications interfaces and an enormous number of controllers and field devices.

Modbus was originally developed by Modicon and today it is managed by the Modbus User Organization. Modbus is an open Master/Slave application protocol, that can be used on several different physical Layers. Modbus is an application-layer messaging protocol, positioned at level 7 of the OSI model.

It provides client/server communication between devices connected on different types of buses or networks. Modbus-RTU (Remote Terminal Unit) means that the Modbus protocol is used on top of a serial line with an RS-232, RS-485 or similar physical interface.

Numerous automation systems have Modbus-RTU interfaces for communication. Modbus devices are certified by the Modbus User Organization for interoperability and conformance to the Modbus specification.

With a Modbus communications port the SC10 is enabled for connection to your communications network for monitoring and control of your sump pumps locally or remotely.